项目介绍(简介、技术特点、应用范围、市场前景、效益分析及对投资者要求)

(中文)

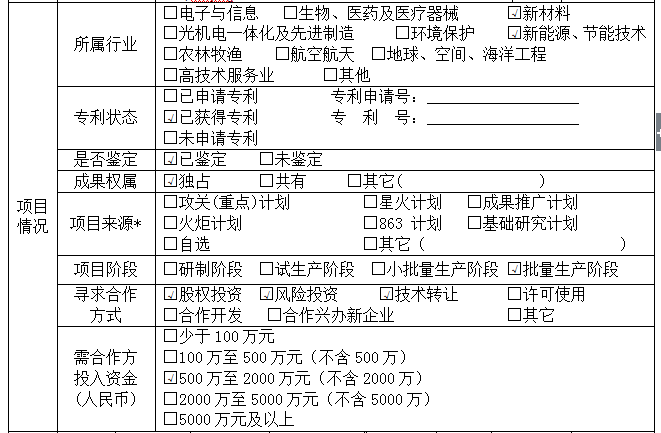

湿法非织布主要是指以超短化学纤维为原料,采用湿法抄纸工艺制备的一种高度均匀的非织布。可广泛应用于制造电池隔膜、过滤材料、无纺布壁纸、农用地膜、茶叶袋、中药袋、屏蔽材料等领域。

本项目针对ES纤维、丙纶纤维、涤纶纤维、维纶纤维、粘胶纤维和天然木浆纤维研究开发了各类纤维单独抄造或多种纤维混抄的湿法无纺布制备技术及装置。在纤维束的疏解分散、浆液过滤、成网、烘干定型等多方面进行了创新性的设计,浆液分散均匀、稳定、无泡,成网均匀,湿膜强度高,烘干过程中无粘网粘缸现象。

基于本项目生产的超细聚烯烃纤维湿法非织布以成功应用于碱性电池隔膜、过滤材料等。

本项目单套装置投资费用约需100万元,日生产能力约为1吨。

(英文)

The wet nonwoven fabric mainly refers to the ultra short chemical fiber as raw material. It is a kind of highly uniform non woven fabric prepared by wet paper making process. It can be widely used in the manufacture of batteries separators, filtering materials, non-woven fabrics wallpaper, agricultural membrane, tea bags, traditional Chinese medicine bags, shielding materials and other fields. Based on ES fiber, polypropylene fiber, polyester fiber, vinylon fiber, viscose fiber and natural wood pulp fiber, a set of wet nonwoven fabric preparation technology and device is prepared. It is suitable for all kinds of fiber making or more fiber mixed copy. The innovative design of various aspects such as relief, dispersion, slurry filtration, mesh forming, drying, shaping and so on. The slurry can be dispersed evenly, stably, without foam, uniform in mesh, high strength of wet membrane and no sticky net in the drying process.

The ultrafine polyolefin fiber wet nonwoven fabric produced by this project has been successfully applied to alkaline battery separator, filter material and so on.

The investment cost of this project is about 1 million Yuan, and the daily production capacity is about 1 tons.