项目介绍(简介、技术特点、应用范围、市场前景、效益分析及对投资者要求)

(中文)

目前的薄膜在线测厚装置多数是基于高能射线(γ-射线、电子束、X射线)穿透薄膜后能量衰减的基本原理进行非接触式在线测厚。本质上所测试的结果与薄膜的面密度相关。对于密度确定的实体薄膜,该数据可进一步转换为薄膜的面密度。而对于多孔膜而言,其孔结构不可能完全均匀,因此对于薄膜的不同部位,其密度是无法确定的。因此,对于多孔膜,无法通过上述方式实施在线测厚。

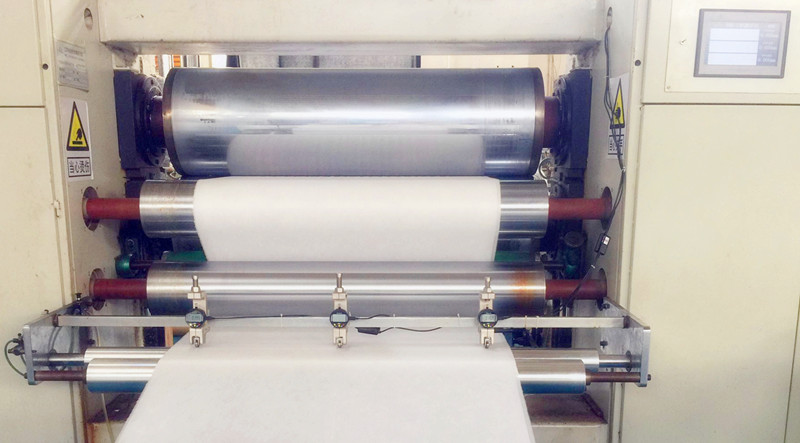

本项目提供的滚轮式膜材料在线测厚装置属于接触式检测,可以直接测量出多孔膜的真实厚度,主要用于高分子膜材料生产过程、热轧定型过程的在线厚度检测和厚度控制。该装置由机架、滚轮测头、压力传感器、数据处理及显示系统构成。通常该装置设三个检测头,分别检测薄膜两边和中间部位的厚度,可以实时获取三个部位的薄膜厚度。如果需要也可设更多的检测头。测试数据可以与控制系统连接,实现在线自动控制。

本项目单套三点式检测装置造价约为6万元。

(英文)

At present, most of the on-line membrane thickness measuring devices are based on the principle of energy attenuation after high-energy ray (gamma ray, electron beam and X ray) penetrating the membrane for non-contact on-line thickness measurement. The results of the tests are essentially related to the surface densities of the membranes. For density-determined membranes, the data can be further converted to the surface density of the membrane. For porous membranes, the pore structure can not be completely uniform, so the density of the membranes is uncertain. Therefore, the on-line thickness measurement cannot be carried out for the porous membrane.

The roller type membrane material on-line thickness measuring device provided in this project belongs to the contact type detection. It can directly measure the true thickness of the porous membrane. It is mainly used in the production process of polymer membrane materials and the on-line thickness measurement and thickness control of the hot rolling molding process. The device is composed of a frame, a roller detection head, a pressure sensor, a data processing and display system.Generally, the device is provided with three detecting heads to detect the thickness of both sides and the middle part of the membrane separately. It can obtain the membrane thickness of three parts in real time. If necessary, you can also set more detection head. The test data can be connected with the previous process to achieve on-line automatic control.

The cost of the three point testing device is about 60 thousand Yuan.